Description

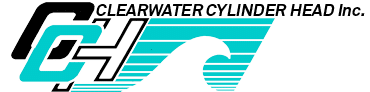

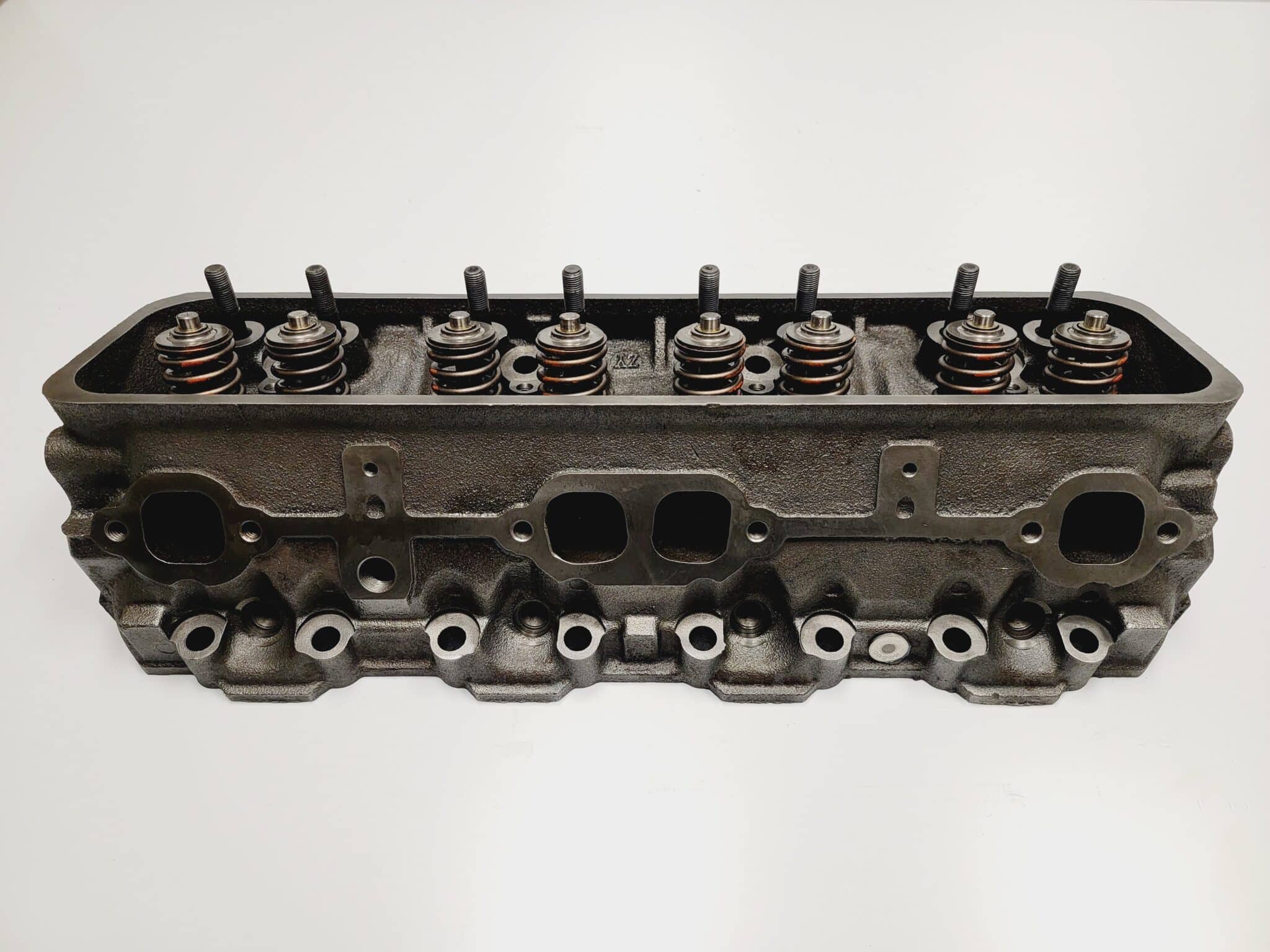

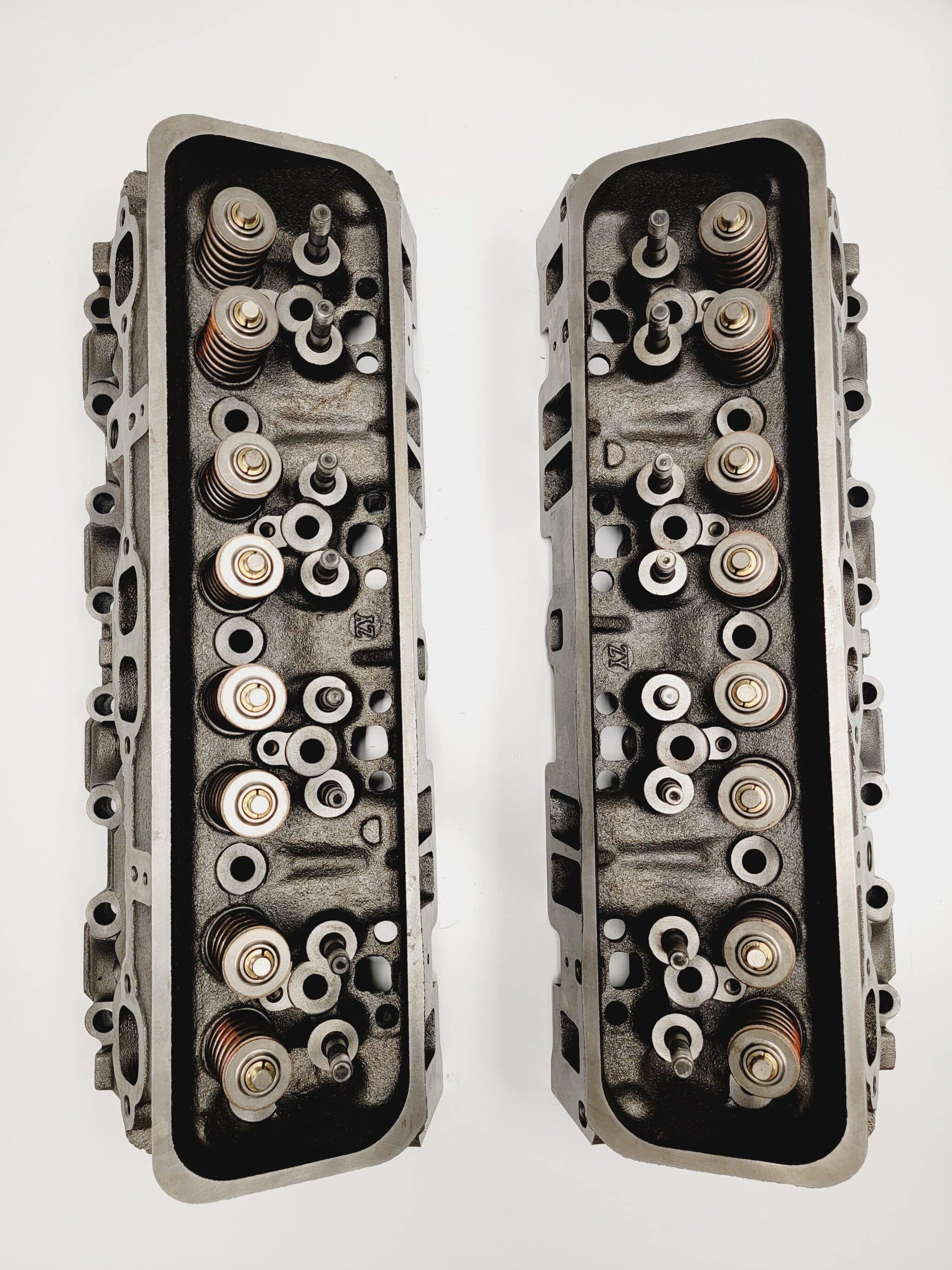

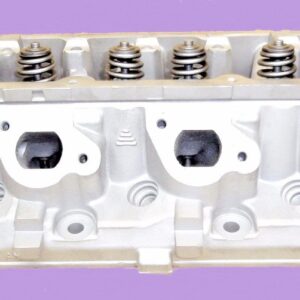

NEW CHEVY GM MARINE 350 906 062 V8 VORTEC INCONEL VALVES

WHAT ARE INCONEL VALVES AND WHY YOU NEED THEM: https://www.prayoontoracing.com/product-page/engine-valves-inconel-exhaust

CHECK OUT OUR OTHER PRODUCTS: https://www.cylinder-heads.com/product-category/chevy/

NEW FITS GM CHEVY 350 VORTEC #906/062 CYLINDER HEAD. THIS HEAD IS COMPLETE WITH VALVES AND SPRINGS. THIS IS A AFTERMARKET HEAD AND IS MUCH THICKER AND STRONGER IN ALL THE CRITICAL AREAS. FITS 1996 to 2002 THIS HEAD WILL HAVE ALL EXHAUST VALVES UPGRADED TO INCONEL.

65 POUNDS EACH

THIS HEAD COMES WITH ALL NEW PEP BRAND VALVES AND SPRINGS!

CHEVROLET 1500 PICKUP 96-99 CHEVROLET 2500 PICKUP 96-99

CHEVROLET VAN 96 -2002

ESCALADE 99-00

GMC 1500 PICKUP 96-99

GMC 2500 PICKUP 96-99

GMC VAN 96 2002

SUBURBAN 1500 96-99

TAHOE 96 2000

YUKON 1996-2000

THIS HEAD FITS YEARS 1996- 2002 PLEASE CHECK YOUR HEAD TO MAKE SURE IT IS THE SAME.

CORE RETURN REQUIRED.

A cylinder head is an essential component of an internal combustion engine. It sits atop the engine block and forms the top of the combustion chamber. It contains the intake and exhaust valves, spark plugs, and fuel injectors, all of which play critical roles in the engine’s operation. During the engine’s operation, the cylinder head seals the top of the combustion chamber to contain the extreme pressures and temperatures generated during the combustion process. The intake valves allow the air-fuel mixture to enter the combustion chamber, while the exhaust valves allow the burned gases to exit. The spark plugs ignite the air-fuel mixture, initiating the combustion process. The fuel injectors ensure that the correct amount of fuel is delivered to the combustion chamber. Overall, the cylinder head is responsible for controlling the flow of air and fuel into the combustion chamber and the evacuation of exhaust gases, ultimately contributing to the engine’s performance and efficiency.

Marine cylinder heads typically have to withstand harsher conditions such as saltwater exposure, so stainless steel valves or Inconel valves which are more resistant to corrosion compared to regular car and truck cylinder heads.

PLEASE INCLUDE YOUR AREA CODE AND TELEPHONE NUMBER

Clearwater Cylinder Head, Inc. thoroughly cleans, inspects, and pressure tests all our cylinder heads. All seat and guide work is performed as needed on the lastest state of the art Serdi or Sunnen seat and guide machine. The head then moves on to a Rottlier CBN resurfacing machine where it is cut to the required RMA finish. We then install a quality valve seal and pull a vacuum on each valve to insure there is a perfect seal between the valve and the seat. All machine work performed on the latest state of the art equipment. Head is complete and ready for installation.

WE ARE A HUGE CYLINDER HEAD SHOP WITH THOUSANDS OF HEADS IN STOCK. WE DEAL WITH ALL MAKE AND MODEL CYLINDER HEADS. IF YOU DO NOT SEE THE CYLINDER HEAD YOU NEED PLEASE CONTACT US 1-800-572-1963.

HAVE A RARE OR HARD TO FIND CYLINDER HEAD? LET US REBUILD YOUR CYLINDER HEAD FOR YOU.

Hours of operation Monday – Friday 8 AM to 5 PM EST

SHIPPING RATE APPLIES TO CONTINENTAL UNITED STATES ONLY. ALASKA, HAWAII, GUAM, VIRGIN ISLANDS, AND PUERTO RICO PLEASE E-MAIL OR CALL FOR SHIPPING RATES

SHIPPING INFORMATION: We ship worldwide.

Insurance, packaging, and handling are all included in the shipping price.

International Bidders, when inquiring about shipping fees please include city, country AND POSTAL CODE.

YOUR OLD CYLINDER HEAD:

We have no up-front core charge and we give you 30 days to return the core.

We make it easy for you to return your core as we provide you with a prepaid UPS peel and stick return shipping label located with the invoice on the outside of the box behind the plastic. Just put your core head in the box that you received your new/rebuilt head in and attach the prepaid peel and stick label. You may then give the box to any UPS driver you may see, or take the box to any UPS pickup point. We will accept your old cylinder head no matter what is wrong with it as long as it includes all the parts that the new head came with. You will never be charged extra because your old head is damaged. Cracked head? OK! Bent valves? NO PROBLEM! Head taken apart? UNDERSTANDABLE! (as long as you put all of the parts in the box). We have no up-front core charge.

WARRANTY INFORMATION: Clearwater Cylinder Head, Inc. provides a TWO(2) year unlimited mileage warranty. A copy of the warranty card will be enclosed with your invoice.

Clearwater Cylinder Head, Inc.

5100 Ulmerton Road #2

Clearwater, FL 33760 USA

Clearwater Cylinder Head, Inc. is dedicated to quality craftsmanship and is pleased to offer this warranty. We invite you to read this entire document carefully prior to installing your cylinder head.

Please do not hesitate to contact us should you have any questions.

1) Acceptance of this head constitutes acceptance of this warranty.

2) Heat tab must be in place on head, not altered or melted.

3) Any claim must be returned to Clearwater Cylinder Head, Inc. for inspection. A copy of invoice must accompany head. A Return Authorization number must be obtained.

4) Only 1 (one) warranty per purchase.

5) Warranty begins at the date of purchase.

6) No incidental, consequential, punitive or over the road damages.

N O L A B O R

WARRANTY COVERS:

Parts Warranty only – All original cylinder heads must be returned for warranty.

WARRANTY DOES NOT COVER:

1) Damage caused by improper installation, accidental over heating, abuse or neglect.

2) Loss of time, use of vehicle, phone calls, inconvenience or consequential charges.

3) Fluids, tow charges, rentals or diagnosis.

4) Repairs made without prior authorization will void all warranties.

5) No warranty on Commercial, Industrial Racing/ Pro stock or Marine Use

If you are not in the United States and you want a shipping quote please include your country and postal/zip code when inquiring.

Replacing a marine cylinder head is a delicate and important task that requires specialized knowledge and skills to ensure the engine operates smoothly and efficiently. It is recommended to consult a professional marine mechanic or technician who has experience working with marine engines to properly diagnose the issue and perform the replacement, as any mistakes in the process could cause further damage to the engine or compromise its performance on the water. Regular maintenance and inspections can also help prevent the need for major replacement work in the future. Replacing a marine cylinder head is a crucial task, as the cylinder head plays a vital role in the engine’s combustion process. It is important to consider factors such as the engine model, make, and specifications when selecting a replacement cylinder head. Additionally, proper alignment, torque settings, and gasket installation are essential to ensure a secure and leak-free fit. Given the complexity and precision required, seeking assistance from a qualified marine mechanic or technician with expertise in marine engines is strongly recommended. Additionally, routine maintenance and inspections can help identify any issues early on and prevent the need for major replacements in the future.

A marine engine, like other internal combustion engines, operates by converting fuel and air into mechanical energy through a series of controlled explosions in the combustion chambers. In a typical four-stroke marine engine cycle, air is drawn into the combustion chamber as the piston moves downward on the intake stroke, then the intake valve closes and the piston moves back up to compress the air in the compression stroke. The fuel is injected or mixed with the air at this point, and the compressed air-fuel mixture is ignited by a spark plug in gasoline engines or by compression in diesel engines, resulting in an explosion that drives the piston down in the power stroke. Finally, the exhaust valve opens, and the piston pushes the burned gases out on the exhaust stroke before the cycle repeats. This continuous process generates the power needed to propel the boat through the water. Regular maintenance, proper fuel and oil levels, and good operating practices are essential to keeping a marine engine functioning properly and efficiently.

Common problems that marine engines may encounter include issues with cooling systems, fuel delivery, electrical components, and mechanical wear and tear. Cooling system problems, such as clogged raw water intake filters or malfunctioning impellers, can lead to overheating and engine damage. Fuel delivery issues, like dirty filters or water contamination, can cause rough idling or stalling. Electrical problems, such as corroded connections or faulty sensors, may result in starting difficulties or erratic engine performance. Mechanical wear from lack of maintenance or incorrect operation can lead to issues like piston scuffing, valve damage, or bearing failure. Regular maintenance, proper inspection, and prompt addressing of any issues can help prevent these problems and keep the marine engine running smoothly.

Marine engine gaskets are essential components that create a seal between engine parts to prevent fluid or gas leaks and maintain proper compression in the engine cylinders. These gaskets are typically made of materials like graphite, rubber, or metal, depending on the specific application and engine requirements. Common types of marine engine gaskets include head gaskets, exhaust gaskets, intake manifold gaskets, and oil pan gaskets. Proper installation and maintenance of gaskets are crucial for the smooth operation and longevity of a marine engine, as any gasket failure can lead to significant engine damage or performance issues. Regular inspection, replacement when necessary, and using quality gaskets designed for marine applications are important practices to ensure the reliability and efficiency of a marine engine.

The lifespan of a marine engine can vary depending on several factors, including the engine type, manufacturer, maintenance schedule, operating conditions, and usage. Generally, well-maintained marine engines can last anywhere from 1,500 to 3,000 hours or more before requiring a major overhaul or replacement. Proper care and routine maintenance, such as regular oil changes, checking fluid levels, monitoring engine temperature, and following manufacturer guidelines, can help extend the life of a marine engine. It’s also important to avoid overloading the engine, operating at excessive speeds for prolonged periods, or neglecting maintenance tasks, as these can contribute to premature wear and shorten the engine’s overall lifespan.

A turbocharged marine engine is equipped with a turbocharger, which is a forced induction device that increases the engine’s power output by compressing the incoming air to produce more oxygen for combustion. The turbocharger consists of a turbine and a compressor linked by a shaft. As the engine’s exhaust gases pass through the turbine, it spins the turbine wheel, which is connected to the compressor wheel. The compressor wheel forces air into the engine’s intake manifold at a higher pressure, resulting in increased power and efficiency. Turbocharged marine engines are commonly used in larger vessels to improve performance and fuel efficiency while maintaining a compact size and weight. Proper maintenance, monitoring boost levels, and ensuring sufficient cooling are essential for the reliable operation of turbocharged marine engines. Turbocharged engines have been used in large scale operations as well as smaller scale operations where power is needed to drive the vessels to their destinations.

NEW CHEVY GM MARINE 350 906 062 V8 VORTEC INCOLNEL VALVES

Reviews

There are no reviews yet.