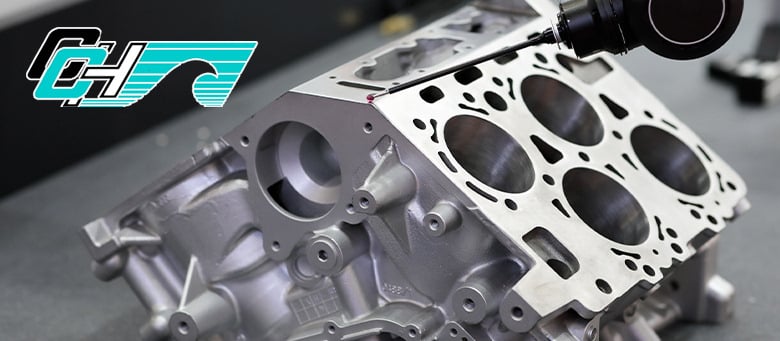

The cylinder head is an integral part of any vehicle’s engine. If you are concerned that your cylinder head may be damaged or need replacing, then you’ll want to inspect this part thoroughly to ensure that it’s repaired or replaced as soon as possible. Today, we’re going to share our complete guide to inspecting cylinder heads to make sure that you remain safe on the road with a fully-functioning engine.

First Identify The Cylinder Head

Before you can inspect your cylinder head, you need to make sure you know exactly where this part is and the type of cylinder head your vehicle has. Between the #4 and #5 pushrods, you’ll find the casting number. 850-1100 heads will have a heater tap that sits at 90 degrees and a small space between the valve cover and thermostat housing. 1275 heads have an angled heater tap with a larger space between the valve cover and thermostat housing. You’ll want to make sure you know what type of cylinder head you have should you need it replaced, but a mechanic will also be able to assist with this task if needed.

Check The Cylinder Head For Straightness

The next step in this process is to check the cylinder head for straightness. Make sure you clean the surface of the cylinder head first, which you can do with a brake cleaner and paper towels. Ensure you remove any debris that might impact your measurements, so you can get an accurate idea of the condition of your cylinder head. You’ll then need to use a straight edge to measure the cylinder head, which you’ll place on the cylinder head’s face. A feeler gauge can help you to check for any gaps and identify if the cylinder head is still straight or not. If you find that the clearance between the surface and the straight edge is higher than the maximum limit for your engine, then you’ll need to either resurface the part or consider replacing it.

Check The Cylinder Heads For Cracks

A very common issue with cylinder heads is a crack on the surface. Cracking is a clear indication that your cylinder head is very damaged and will likely need replacing or repairing. The sooner you can identify cracks in this part, the less likely you will be to do permanent damage to your engine. Cracks can result in loss of power within your engine or poor performance when driving. However, in the long run, they might lead to engine failure or overheating, which can be far more costly to repair than just replacing your cylinder head.

There are multiple testing methods when it comes to inspecting a cylinder head. A dry magnetic particle inspection is ideal for cast iron cylinder heads, whereas a wet magnetic particle inspection is a messier option that is only used in very rare circumstances. For aluminum castings, we recommend a dye penetrant inspection or pressure testing, which can be used to find small pin holes in cast iron or aluminum. A professional will be able to guide you through the best inspection option for your needs or take care of the task by themselves to identify any cracks and holes.

Do A Cylinder Head Compression Test

Wear and tear to your cylinder head can be tested with a compression tester, which you can either buy in a hardware store or hire for the task. This compression testing will allow you to see if there is any leakage to the cylinder head, poorly sealed valves or worn piston rings. The figures that you get after performing this test should land within 10% of each other or the manufacturer’s figure to identify that the engine is in good condition. When one cylinder has a lower result, then it’s clear there is an issue in this area, and further testing or repairs are required.

Inspect the Head Bolts

While your head bolts might seem like a small part of your cylinder head, they are critical for combustion and ensuring the engine runs smoothly. The bolts keep the cylinder head in the engine block and ensure the head gasket seals well. Start by checking for signs of wear and tear to the bolts, which will increase the chance of failure. The length of the bolts should also be reviewed, as some may be stretched and distorted. When the bolt’s length isn’t correct, this means it won’t seal properly and could increase the chance of leaks.

Test The Cylinder Head Temperature Sensor

We typically recommend that you hire a mechanic to test the cylinder head temperature sensor. You may notice issues with your engine performance, a longer cranking time, or the “Check Engine Light” illuminating if you have issues in this area. As this task is more challenging to perform, a professional mechanic can do this without causing any further damage to the cylinder head.

Always Purchase Cylinder Heads with a Warranty

When it comes to replacing or repairing your cylinder head, we always recommend working with a professional to get their recommendation for the best route of action to take. If you do need to purchase a new cylinder head, then always make sure it comes with a warranty. Take your time to check out the exact terms of this warranty so that you know what you are covered for and how long this coverage will last. Make sure you ask any questions ahead of making this expensive purchase so you aren’t left in a similar situation again, needing another replacement in the near future.

Learning how to inspect a cylinder head can help you to identify cracks and issues before they develop into a bigger problem. Follow these steps one at a time to find any issues with your cylinder head, and then work with a mechanic where needed to ensure you replace or repair it correctly. The cylinder head is critical for the overall functioning of your engine and vehicle, so keeping it in top condition will ensure you enjoy excellent engine power and reliable performance.

CYLINDER HEAD INSPECTION EXPERTS | CLEARWATER CYLINDER HEAD

Clearwater Cylinder Head (CCH) is a parts company focusing on cylinder heads. By specializing in providing warranty-backed rebuilt heads for a wide range of vehicles, we have grown to be one the largest aftermarket cylinder head companies in North America. Not sure which cylinder head fits your vehicle? Please give us a call at 800-572-1963 so we can help you identify the perfect cylinder head for your car, truck, or boat.

“I received the remanufactured head within two weeks. It was carefully packed and delivered by FedEx. The head was an exact replacement for my warped Volvo cylinder head. I had it checked out by a local machine shop. I have completed the installation, the car started up immediately, compression issues solved. I highly recommend this business.”

- Pete Confar